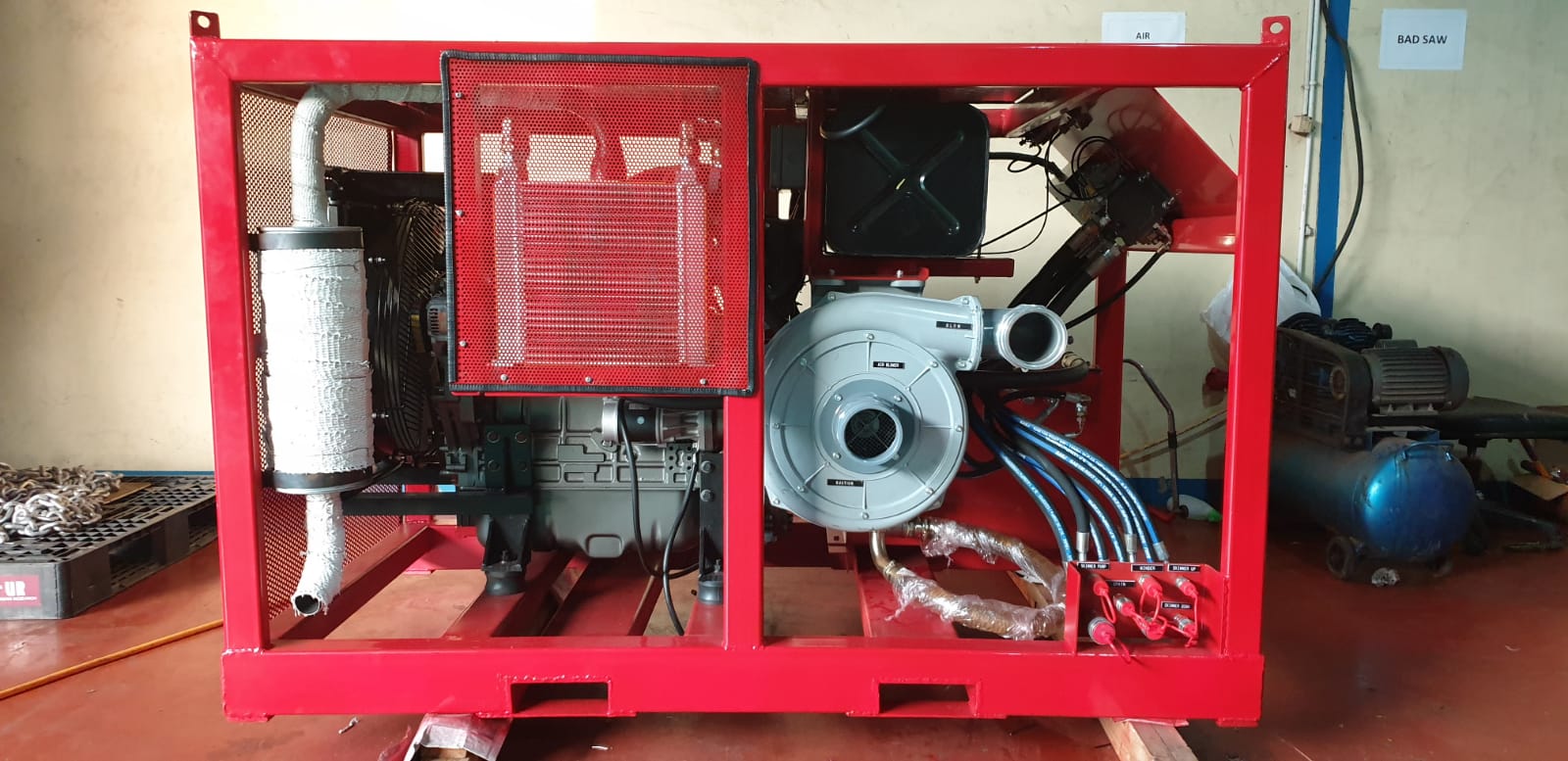

Power Pack Winder – Unit Listrik Khusus Penggulung Boom Elektrik Oil Spill Response

Electric winder merevolusi deployment oil boom dari proses manual 30 menit menjadi one-touch 3 menit operation. Namun, keberhasilannya bergantung pada power pack winder – genset khusus dengan precise torque control, stable voltage, dan high starting current untuk motor 3-5 HP winder heavy duty.

Power pack ini dirancang untuk electric winder 100 EC dan model serupa, memastikan deployment + recovery boom 100-150m tanpa putus daya di pelabuhan atau offshore.

Apa Itu Power Pack Winder?

Power pack winder adalah genset diesel khusus dengan high surge capacity (200-300% rated power) untuk menyalakan motor induksi winder yang membutuhkan starting current 6x running current. Dilengkapi soft starter dan voltage stabilizer untuk proteksi motor winding.

Spesifikasi winder-optimized:

- Output: 7.5–15 kVA single phase

- Surge capacity: 300% x 10 detik

- Engine: Diesel 1800 RPM low vibration

- Voltage regulation: ±0.5% under load

- Weight: 280–420 kg

- Tank: 80L (20 jam continuous)

Direct coupling ke winder drum motor via heavy-duty cable.

Kompatibilitas dengan Winder Types

| Winder Model | Power Rating | Boom Capacity | Power Pack Dibutuhkan |

| KHW-25 | 3 HP | 25-50m | 7.5 kVA |

| Winder 25 WP | 5 HP | 50m | 10 kVA |

| Winder 100 EC | 7.5 HP | 100-150m | 15 kVA |

| Heavy Duty 200m | 10 HP | 200m | 20 kVA |

Winder 100 EC paling populer (15 kVA = 85% market share).

Sistem Kontrol Khusus Winder

| Fitur | Fungsi | Manfaat |

| Soft Starter | Ramp-up current 30 detik | No motor shock |

| Torque Limiter | Auto-cut @150% load | Boom protection |

| Voltage Monitor | ±0.5% regulation | Precise winding |

| Thermal Protection | Engine + motor PTC | Overheat prevention |

| Remote Start | 50m wireless | Safe distance operation |

PLC interlock – winder stop jika power drop.

Keunggulan Power Pack Winder

| Spesifikasi | Nilai | Dampak Deployment |

| Starting kVA | 25 kVA peak | Instant motor start |

| Voltage Dip | <5% @ full load | No winding slip |

| Runtime | 20 jam continuous | 4x deployment cycle |

| Vibration | <3 mm/s RMS | Accurate boom tension |

| Fuel Efficiency | 0.28 L/kWh | 30% hemat diesel |

Deployment cycle: 100m boom → 3 menit vs 25 menit manual.

Aplikasi Deployment Winder Power Pack

Skenario operasional optimal:

- Port Rapid Response – Winder 100 EC + 15 kVA untuk tanker spill

- FSRU Protection – Continuous boom cycling 24/7

- Refinery Drill – Multiple winder training simulasi

- Offshore Platform – Helicopter portable 7.5 kVA untuk emergency

Case study: Pelabuhan Priok Drill 2024 → 150m deployment + recovery 6 menit total dengan power pack 15 kVA.

Spesifikasi Teknis Lengkap

15 kVA Winder Power Pack

– Engine: Perkins 403D-11G 18HP @1800 RPM

– Alternator: Mecc Alte ECO38 brushless

– Voltage: 220V/1φ atau 380V/3φ 50Hz

– Surge: 45 kVA x 10s (300%)

– AVR: Compound + PMG excitation

– Soft start: Electronic ramp controller

Winder Interface

– Socket: 32A 5-pin CEE marine

– Cable: 25mm² H07RN-F 20m

– Control: PLC + HMI 7″ touchscreen

– Interlock: E-stop + overload relay

Marine Protection

– Canopy: IP65 soundproof 72 dB

– Baseframe: Anti-vibration mount

– Fuel tank: 80L bunded (110% capacity)

ISO 8528 G3 performance class.

Setup dan Deployment Cepat

Prosedur 10 menit koneksi:

1. Position winder + power pack (2m clearance)

2. Cable connection 32A CEE lock (2 menit)

3. PLC sync winder-power pack handshake (1 menit)

4. Load test no-load rotation check (2 menit)

5. Boom coupling quick-release shaft (3 menit)

6. Remote arming safety interlock clear (30 detik)

Hot swap <5 menit antar power pack.

Maintenance Winder-Specific

| Interval | Fokus | Durasi |

| Pre-deployment | Voltage + torque check | 5 menit |

| 50 jam | V-belt tension + AVR calibration | 20 menit |

| 250 jam | Motor coupling inspection | 45 menit |

| 500 jam | Soft starter diagnostic | 1 jam |

| 1000 jam | Full AVR + alternator test | 2 jam |

MTBF >5000 jam winder operation.

Perbandingan dengan Shore Power

| Sumber | Surge Capacity | Voltage Stability | Runtime | Cost |

| Power Pack Winder | 300% | ±0.5% | 20 jam | Medium |

| Shore Power | 100% | ±2% | Unlimited | Infra mahal |

| Vessel Aux Genset | 150% | ±1.5% | 8 jam | Fuel expensive |

| Manual Winder | N/A | N/A | Manpower | Labor intensive |

3x faster deployment + zero manpower.

Standar Sertifikasi Winder Power

Memenuhi:

- ISO 8528-5 Performance class G3

- IEC 60034-1 Rotating electrical machines

- NEMA MG1 Motor-generator standards

- IMO Res. A.689(17) Safe operation machinery

- ATEX Zone 2 hazardous area

Marine type approved DNV-GL, Lloyd’s Register.

Kesimpulan

Power pack winder mengubah electric winder dari konsep menjadi deployment powerhouse dengan surge power, precise control, dan marine durability. Solusi ini mempersingkat response time dari jam menjadi menit, meningkatkan boom utilization 400%, dan menghemat manpower secara drastis.

Lengkapi electric winder fleet Anda dengan dedicated power pack untuk rapid deployment capability industri kelas dunia.